Scope of activities

- Find professional solutions for being an outstanding market player

- Achieve better and better breeding / feeding values

- Strong control of incoming raw materials/ storage/ production/ feeding efficiency

- Implement tests in breeding/ feeding from small to large scale like settting up a new test station for reliable and effective evaluations

- Explore new ingredients, additives

- Create a solid nutritional background

- Conduct huge quantity of accredited laboratory tests

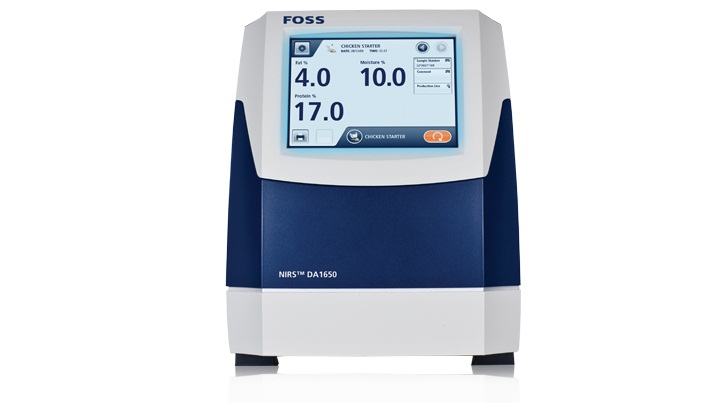

- Use of a brand new NIR (near infrared) device for more measured results

- Tightened analyses of incoming raw materials, i. e. moisture content and sensorial measurements in case of every incoming raw material

- Safe raw material storage through controlled storage conditions and pest control

Continuous improvements in the feed mill

Our feed mill produces approximately 25.000 tons of feed per year, which quantity is growing every year. Feed production capacity has been recently duplicated up to 10 t/h of pelleted rabbit feed in order to achieve a production availability, which fulfils our farms need. Brand new production machines with new modern control software are implemented. We keep the full production procedure in our own hands to ensure the maximum feed security and to get outstanding feed. We use the best raw materials combined with the best production processes in order to achieve the highest quality feed.

Procedure steps:

- Mixing

- Conditioning

- Granulation

- Cooling

After the mixing procedure transforming a soft feed into a hard pellet is accomplished by compression, extrusion and adhesion. The general process involves passing the feed mixture through a conditioning chamber, where water in the form of steam is added. Moisture provides lubrication for compression and extrusion, and the presence of heat lead to gelatinization of raw starch being on the surface of vegetative ingredients, resulting inadhesion. After granulation we have a hot product, which needs a cooling procedure before undergoing product handling and becoming a finished feed product, which ensures the safe and high quality product.

Standards:

Our feed mill fulfills all relevant EU and national law requirements. The rabbit feed production process is ISO 9001 and ISO 14001 certified. With our work we commit ourselves to quality and protection of the environment. Our feed mill operates according to HACCP principles, based on a certified HACCP system. Our work is based on GMP requirements.

Ecology and Efficiency

Production efficiency and energy consumption are continuously under control, and in addition to that, we try to find new ways to reach the best results (i.e. implementing solar cell fields for being more cost effective)

Local sourcing:

Hungary as manufacturing site provides an advantageous location for fodder production. Over 90% of raw materials are produced in the region. Hungarian agricultural products are 100 % GMO-free.

State of the art technology:

A brand new Merlo front loader machine was purchased for the better cost efficiency.